Lubrication

The maintenance of a bike drivetrain is important for riders who are aiming for high performance standards. This is a collection of technical information on bike drivetrain which should answer some frequently asked questions and assist in searching for the perfect lube.

The topic of chain lubrication can become extremely emotive for one simple reason – every ride is different. What works for one rider, drivetrain, bike and journey may not work as effectively next ride, or for a different rider, or on a diffferent bike. Most cyclists have a natural tendency to help other cyclists, so when someone is lucky enough to find a lubricant that works well for them, they feel completely justified in sharing this secret with others. It is a combination of factors which means that there will always be a lot of discussion on the best lubricant.

Which lube – help me choose?

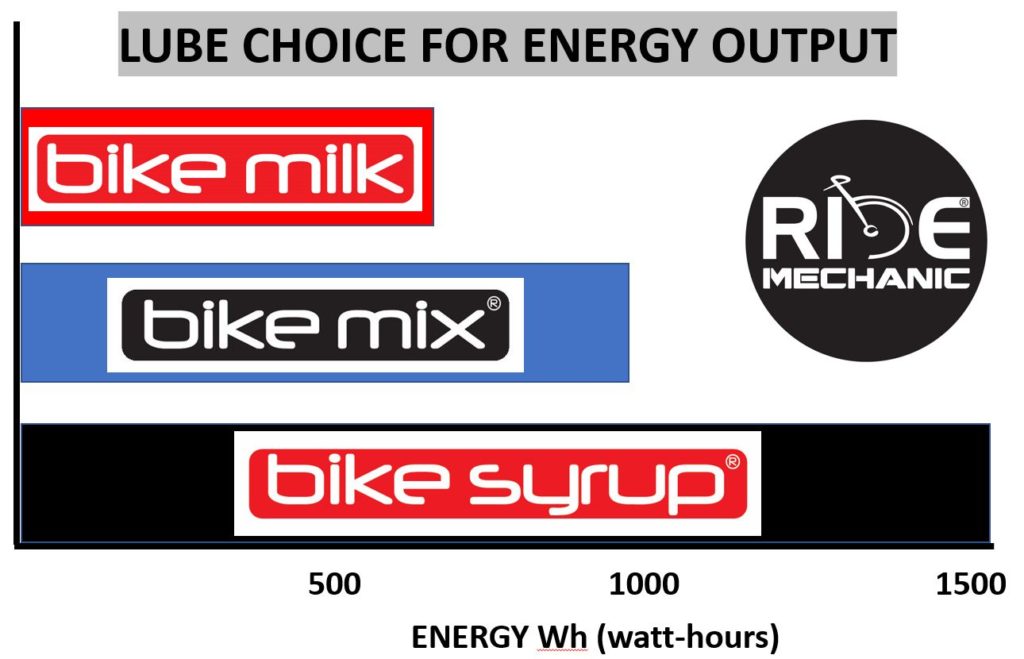

Bike Milk dry and dusty conditions up to 3h riding. Apply frequently. suggested for BMX, XCO, DH, beach and desert.

Bike Mix is the all-purpose lube which is a selected combination of wet/dry components suitable for any bike and any ride without collecting too much grime and gunk. It is used routinely in 24h MTB events and good pre-loading results in around 14h constant riding without needing to reapply lube. It has been used in the 4400km Tour Divide event with nightly application averaging 220km riding per day in various riding conditions.

Bike Syrup is the durable and quiet option for e-bike with motor assist; endurance road riding; high power output riders; road commuters wanting 600km+ between lube applications; road riders who want the convenience of applying immediately pre-ride; riding in wet conditions where external surface coating can be beneficial.

How do I apply lube?

Both BIKE MIX and BIKE MILK are low viscosity clean-penetrate-protect lubes which work most effectively when applied to a moving chain. The movement of the links, pins and rollers during application directs the fluid onto the hidden moving surfaces of the pins, rollers and plates. The lube penetrates these areas to dissolve grease and flush out dirt and other residues as the moving chain rotates on the bike. These contaminants become mobile and can be removed from the bicycle chain by wiping the surface with a dry, lint-free cloth. After penetrating, flushing and cleaning each chain link the the lube dries to form a lubricating and protective waterproof film on all contact points of the chain.

BIKE SYRUP has higher viscosity for enhanced tenacity and durability in use. It does not have a combined cleaning function. The chain should cleaned prior to loading, either by thoroughly wiping the external surface or using a full degrease and dry. Warming the chain when applying BIKE SYRUP assist the flow and penetration.

By applying the lube to a reverse rotating chain the load bearing zones (i.e. those in contact during use in forward rotation) are opened up for better loading. The lube can then bind into those areas of the pins and rollers to effectively seal access points to the inner surfaces preventing further ingress of water, dirt and other contaminants.

What causes drivetrain noise?

Excessive drivetrain noise can be caused by several things e.g. noisy jockey wheels, misaligned derailleur, poor meshing of chain and sprockets, grit adhesion on outside of chain during wet rides etc and cannot always “blame” the noise on the lubricant.

If there is no lube inside a chain the characteristic and frustrating grinding noise comes from the metal-on-metal contact surfaces inside the chain. This is a noise which no rider wants to accompany them on their ride!!

To check if lube levels are sufficient squeeze the chain firmly betwen thumb and forefinger. If lube can be squeezed out of the chain between rollers and plates and leaves a coating residue on the finger/thumb then lube levels should be sufficient. A top-up lube is advised if no significant lube can be squeezed off the chain in this way. Suggested residual levels of well lubed chains are indicated below.

What is difference between wet and dry lubes?

In very simple terms, a wet lubricant remains a fluid which can flow around inside & outside the chain to give long-lasting lubrication on inside and outside surfaces. A dry lubricant forms a film and feels “dry” to touch. This video is a good demonstration comparing wet and dry chain lubricants.

It is intuitive that a wet lube will be attractive to dust & grime and under riding conditions forms a dark grit paste that can cause noise and become messy for the whole drivetrain including jockey wheels, sprockets and chainrings. In some riding conditions with low dust (e.g. very cold snow and ice) a wet lube is perfect with no buildup of grime. However, most riders will encounter dust and a dry lube is preferred to limit the buildup. Most riders prefer a dry lube. The complication is that there is a direct relationship between lube durability and flow. A wet lube will last longer than a dry lube.

The wet lube moves within the pins, bushings and rollers and this very feature which makes it tenaciously stick to the metal components, is the feature which attracts the dirt. A dry lube creates a film which does not behave like a fluid. It moves more like a paste and squeezes off the metal surfaces. It also needs to be fully pre-loaded into the chain pin/bushing cavity. When using a dry lube the chain should be cleaned before applying so that the lube can penetrate into the cavities of the chain. Most dry lubes incorporate a dual function clean/lube where the carrier solvent can flush out the chain and clean any buildup in the small “lube delivery” gaps between the bushings. If these gaps are too small or clogged then lube will not penetrate onto the pin surface where most contact wear occurs.

What is the “reservoir effect”?

A detailed investigation of Bike Milk performance has been carried out using a penetrating fluorescent dye.

Full report is available here.

In summary, when a clean, degreased and dry 10sp bushingless chain is well conditioned with Bike Milk it is lubricated and protected in the key areas it is required;

- between the outside of pins and the inside of the spigots,

- between the outside of the spigots and the rollers,

- between the outer plates and the inner plates.

Explain the parts in a bike chain?

The chain on almost every bike now is “bushingless”. The original invention by Guy Dupoyet was patented in 1978 by Compagnie des Transmissions Mecaniques Sedis and the original patent is here

A good quality bushingless chain can last up to 10,000km with good lubrication. They shift well and can be made light and narrow. This development is arguably the biggest technical improvement which has happened to a bike over the last 30 years. The parts of a bicycle chain are: outer plate, roller, pin, inner plate. The load transfer is from the outer plate via the fixed pin pulling and rotating on the inner link plate bushing surfaces. Load transfer from inner plate onto outer plate is via the inner bushing surface pulling and rotating on pin. A chain does not elongate along pin-pin distance of outer plate which always remains 12.7mm. Wear is on pin and bushing surfaces along inner plates where there is movement and load.

The components of a chain and chain wear are demonstrated in this video.

Does my new chain have a lube coating?

The efficiencies of new chains coated with factory lube coating have been tested by Friction Facts and show the tacky nature of the protective factory coating can impact on lubrication efficiency.

How should I clean my chain?

Sometimes the grime buildup needs to be cleaned off. The recommended drivetrain degreaser is Bike Juice. This process can be done on the bike using a simple clip-on chain clean device which has been loaded with liquid Bike Juice concentrate. After rotation remove the device and hose down with water then dry the chain using an Avaqua flush. Another option is to use a volatile light hydrocarbon (use gloves in ventilated flashproof environment) with a toothbrush scrub or a sonicator. Wipe with rag for final clean.

Where is friction loss in a chain?

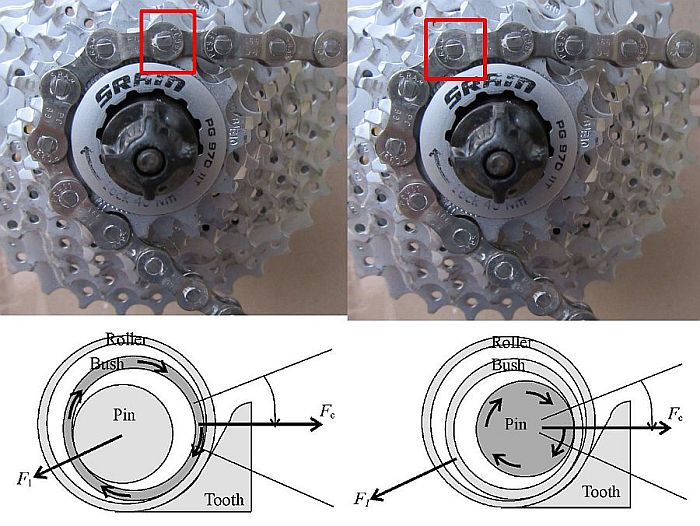

It is well understood that the majority of friction occurs in areas of high load and tension, in particular on the disengagement of the chain from the rear sprocket and then upon engagement at the front chainring. The rest of the time a chain link is not moving under significant load. Also consider that a larger articulation angle in a link under load causes higher friction and wear. Smaller sprockets create higher friction and wear than larger ones. The diagram below outlines the different zones of movement and friction in a chain upon disengagement from an 11T rear sprocket tooth under load.

A close up of this movement is shown in the video and the link articulation angle can be clearly seen on entry into the sprocket from the derailleur and upon exit. Also note there are only 6 teeth contacting the chain at any time. Chain tension in an explosive 1500W burst of power is the equivalent of lifting 150kg a height of 1m in 1 second. In this case the tension on the chain and consequently transferred into the sprocket tooth at disengagement is very high, around 1500N which is high enough to cause metal deformation on the very small surface contact points of the pins and bushing.

How efficient are chain lubes?

Experienced riders intuitively know that a clean and well lubricated chain gives better performance. Can this be quantified? The overall power transfer through the chain is very efficient, around 99% using sprocket ratio 52-21 200W 60rpm (Spicer et al, Journal of Mechanical Design, 2001). In this reputable journal article three different lubricants were tested and no significant quantifiable effect of lubrication could be inferred.

Some other more widely reported laboratory based experiments have been conducted to directly compare the influence of chain lubricants under set conditions. In these experiments a drivetrain is setup on a test rig and a force applied to simulate the load at the rear wheel. Monitoring the friction loss in the drivetrain or the chain wear is used as a quantified indicator of comparative lubricant performance. These findings are used to promote certain types of lubricant as power-saving to improve the efficiency of your power transfer. There are many variables which impact on the efficiency of power transfer and lab rig testing has not yet been carried out on Ride Mechanic lubricants. However we remain very confident that a perfect lubricant can be matched to each rider. Please make time and contact us if you would like advice on optimisation of your drivetrain for optimum performance.

Temperature and chain lubes?

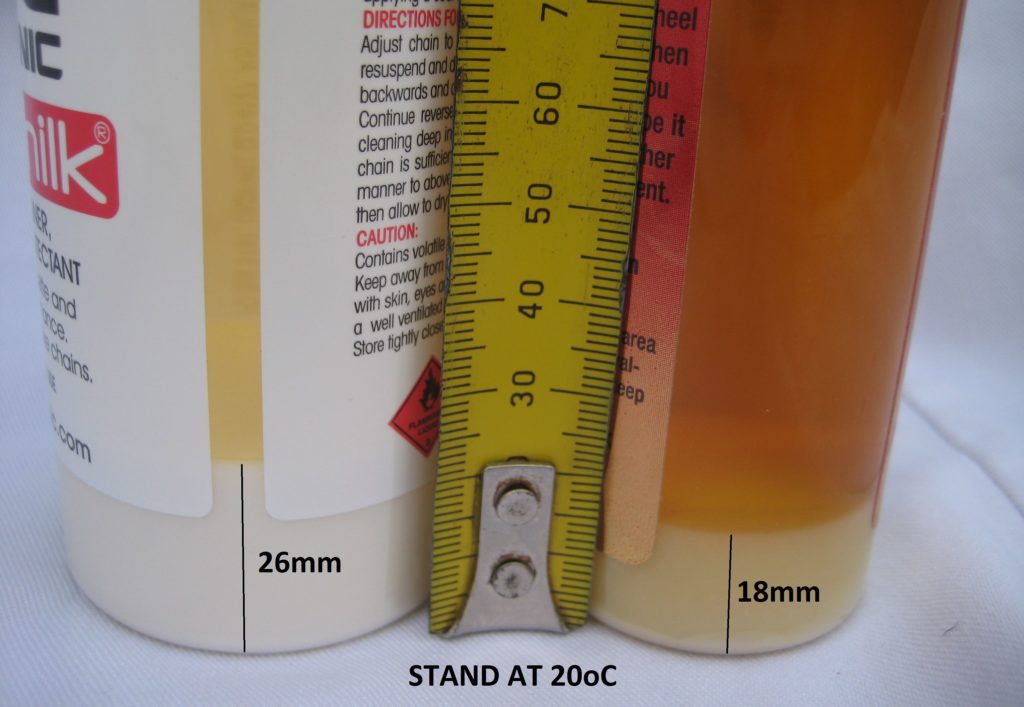

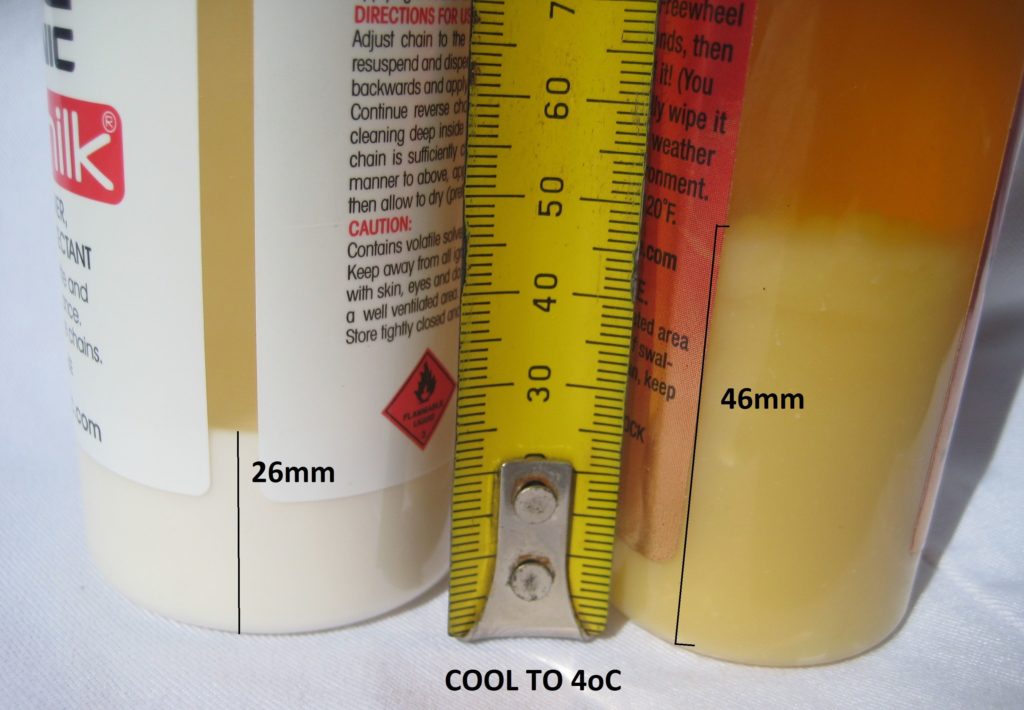

Quite a lot of maintenance work is done in outdoor conditions and the lube bottle can get cold. In low temperature conditions the solid lubricant component in some chain lubes can solidify and no longer flows to penetrate the links and effectively coat the inside contact surfaces of the chain where the lubricant is most required. In the shots below BIKE MILK and another popular wax based “dry” lubricant are compared in pleasant daytime conditions (top) and after cooling at 4oC (bottom). It is clear that the amount of solid lubricant in BIKE MILK does not change at different temperatures. However, the other wax lube product shows much higher levels of undissolved solid lubricant in cold conditions. Some dry lubricants (not BIKE MILK) contain a wax dissolved in a hydrocarbon carrier/cleaner solvent. When the temperature drops, the solubility of the wax decreases. The viscosity increases and the wax component is not applied to the chain and does not perform on the chain as it does in normal conditions.